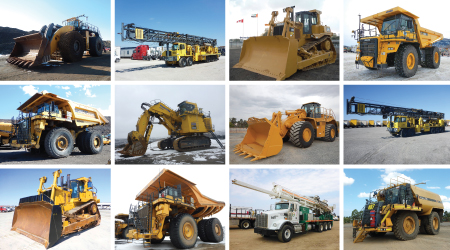

Boost Your Mining Procedures with Costs Quality Mining Equipment Parts and Add-on

Boost Your Mining Procedures with Costs Quality Mining Equipment Parts and Add-on

Blog Article

Unveiling Necessary Mining Devices Parts for Optimal Workflow

In the complex world of mining procedures, the smooth functioning of equipment is paramount. As we dive right into the midsts of mining tools essentials, a more detailed look at the intricate information and performances of these components unveils a remarkable world where performance and integrity are the keystones of success.

Importance of Correct Drill Little Bits

Correct selection and upkeep of drill bits are essential for maximizing mining efficiency and productivity (mining equipment parts). The kind of drill bit picked need to line up with the specific geological problems of the mining site to ensure optimal efficiency.

Routine maintenance of drill bits is equally crucial to make sure long life and efficiency. Dull or broken drill bits can cause decreased drilling speed, increased endure exploration tools, and ultimately, reduced performance. Maintenance tasks may include sharpening, regrinding, or changing used components to maintain the drill little bits in leading functioning condition.

Trick Components in Conveyor Solutions

Efficient material transport in mining operations heavily relies on the performance and stability of key parts in conveyor systems. One vital element is the conveyor belt itself, which brings the materials along the mining website.

Critical Filters for Devices Maintenance

A crucial facet of ensuring the durability and optimum performance of mining devices depends on the precise selection and maintenance of important filters. Filters play a critical role in securing mining machinery from pollutants that can trigger wear and tear, resulting in costly fixings and downtime. Dust, debris, and dirt are prevalent in extracting settings, making the proper filtration system necessary to equipment durability.

Filters in mining devices offer to trap fragments that could penetrate delicate components such as transmissions, hydraulics, and engines. Consistently changing these filters according to maker referrals is imperative to stop blocking and ensure reliable operation. Overlooking filter upkeep can lead to reduced equipment lifespan, reduced efficiency, and raised gas intake.

Necessary Wear Components for Crushers

In the realm of mining equipment maintenance, one crucial aspect that requires interest is the identification and substitute of necessary wear parts for crushers. Crushers play a fundamental duty in the ore processing and material decrease processes within mining operations. Some of the essential wear parts that are important for the effective functioning of crushers consist of the complying with:

** Crusher Liners **: These are important in protecting the crusher covering from deterioration created by the material being squashed.

** Jaw Plates **: Established in jaw crushers, these parts are accountable for crushing the product against a dealt with surface area.

** Mantles and Concaves **: These elements are important in gyratory crushers, where they help in squashing the product into an extra refined type.

Routine evaluation and replacement of these wear components are vital to ensure the crushers operate at their optimum effectiveness, lowering downtime and optimizing productivity in mining procedures. Correct maintenance of these wear parts can considerably impact look at this now the overall efficiency and durability of the crushers, eventually adding to the success of mining tasks.

Role of Hydraulic Cyndrical Tubes in Mining

Playing a critical role in contemporary mining procedures, hydraulic cyndrical tubes are integral components that help with the efficient performance of numerous hefty equipment. These hydraulic cylinders are essential for powering necessary mining equipment such as excavators, drills, excavators, and loaders. One of the primary features of hydraulic cylinders in mining is to offer the pressure required to relocate hefty lots and materials in challenging terrains. The capability of hydraulic cylinders to create tremendous power in a regulated fashion makes them crucial for jobs like lifting, pressing, pulling, and squashing within mining operations.

Hydraulic cyndrical tubes in mining tools are created to withstand harsh operating conditions, including severe temperature levels, high pressures, and hefty tons. In essence, hydraulic cyndrical tubes play a vital duty in boosting the efficiency pop over to these guys and performance of mining procedures worldwide.

Conclusion

Finally, it is critical for mining procedures to utilize correct drill little bits, crucial elements in conveyor systems, critical filters for equipment upkeep, necessary wear components for crushers, and hydraulic cylinders. These crucial mining equipment components play a substantial duty in making sure optimum operations and taking full advantage of effectiveness in the mining industry. By purchasing reliable and top quality devices components, mining companies can boost efficiency and minimize downtime, eventually bring about an extra successful procedure.

In the complex world of mining operations, the smooth performance of devices is extremely important. By investing in premium purification systems and sticking to a rigorous upkeep timetable, mining operations can enhance equipment integrity, lessen downtime, and eventually enhance productivity.

In the realm of mining tools upkeep, one essential element that demands attention is the recognition and replacement of vital wear parts for crushers. These important mining equipment components play a considerable duty in making certain optimal procedures and taking full advantage of performance in check my blog the mining sector. By investing in top quality and reliable tools parts, mining companies can improve efficiency and reduce downtime, eventually leading to a more effective operation.

Report this page